Business Overview

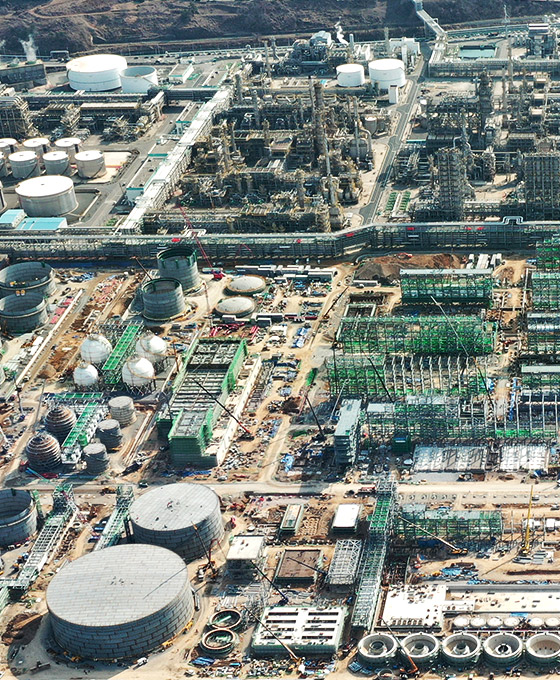

MFC Project

GS Caltex constantly explores new growth drivers while enhancing existing businesses.

The olefin market has strong growth potential, which is why GS Caltex is nurturing olefins as a future growth engine. As the first step in this endeavor, we are constructing a MFC (mixed feed cracker).

The MFC will expand our petrochemical line-up from aromatics to olefins to create a more balanced business portfolio. It will also enhance our presence in the global market.

Project Outline

- Construction period

- 2019~2021 (estimated)

- Investment

- About KRW 2.7 trillion

- Annual production capacity

- 750,000 tons of ethylene, 500,000 tons of polyethylene

- Jobs created

-

2 million during construction (annual)

approx. 500 during operation (direct hiring: 240, indirect hiring: 260)

MFC Process & Advantages

The MFC process at GS Caltex features a flexible design that enables the selective feedstock from existing complex. By-products are upgraded into high value-added products at the existing complex. This implies enhanced profitability. Enhanced cost competitiveness should give us an advantage over our competitors.

Steps are being taken to reduce complexity and raise productivity during the MFC’s construction phase.

- By-products can be provided to existing complex

- Off-gas can be used as feedstock

- Optimized Naphtha for MFC can be supplied from existing complex

Products

High Density Polyethylene

Major olefin product

Ethylene is a major feedstock that goes into making a vast range of chemical products. It is essential to manufacturing products used in everyday life, such as plastics, synthetic rubber, building materials, adhesives, paint, etc.